Three centuries of Rum in bulk

An article by Pekka Nurmi: Photos Jaani Vaahtera

Three centuries of Rum

A tower of steel containers lies in waiting at Amsterdam harbour. Few people realise that the containers are hiding up to 6,000,000 litres of Rum.

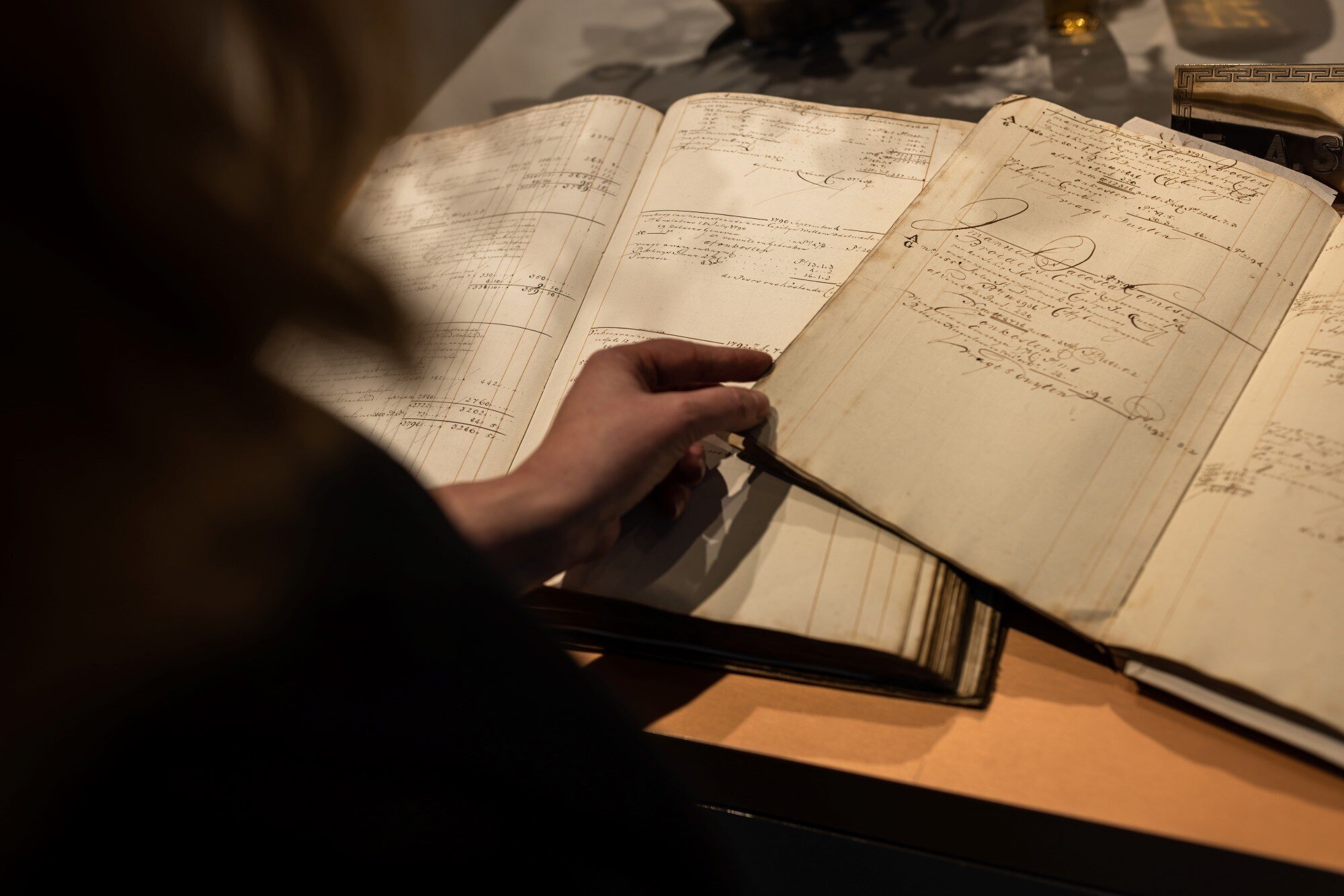

Rum has an unmistakeable air of maritime romance. The shipment of Rum from the Caribbean colonies to Europe began as early as in the 17th century. The crossing to the old world over the stormy Atlantic was long and often fraught with danger. The very drink being shipped was also the source of a ship’s crew’s motivation and was used to prevent disease.

Although Rum has its roots in the Caribbean and in South America, Europeans can be credited with its creation. Even in the time of Columbus, sugarcane had made its way to the Caribbean Islands along with European ships, and it proved to be easily cultivated in the local climate. When it was noticed that the plant not only produced sugar but also made for a tasty alcoholic beverage, Rum was exported to Europe with great enthusiasm.

In the 18th century, the popularity of Rum in Europe was so great that, in England, it even overtook the traditional beverage of choice, gin. At the same time a Dutch, familyowned shipping company by the name of E&A Scheer began operations, with its vessels sailing along the Atlantic triangle trade route between Europe, Africa and the West Indies, returning to Europe with Rum and sugar. In the following century, Scheer began to focus increasingly on rum and started to concoct a variety of blends from the rum stock it had in its warehouses. To guarantee speedy delivery and short distances to other parts of Europe, the warehouse was located in Amsterdam.

Not much has changed to this day. E&A Scheer’s head office and warehouses are still in the beautiful city of canals, and after three centuries of operation, the company has an established customer base and operating model. Scheer specialises in bringing bulk rum from Caribbean producing countries to Europe, where the company uses its skills to blend and prepare different kinds of rum for its customers. Its customers are mostly beverage companies from around the world, but some operate in the cosmetics, aroma and food industries.

Carsten Vlierboom, who has been the managing director at E&A Scheer for fifteen years, explains that the demand for rum has risen steadily since the turn of the millennium. The increase in demand is evident in the company’s operations. Since the start of the new millennium, Scheer’s turnaround has increased almost four-fold. Vlierboom believes that one reason for the increase in demand lies in the cocktail boom.

Rum is incredibly versatile. It can be used in an infinite amount of different drinks, and more and more bartenders are realising this. And we’re always looking for something new. Whisky used to be the most popular, but now it seems that its cocktail options have been exhausted and it’s time for a change. Rum has potential, which is visible in the market areas. Currently, Scheer supplies rum to its customers in over 40 countries. The annual quantity of pure alcohol (100 %vol.) delivered is 10 million litres, which is around 33 million bottles of rum. Rum can be manufactured through the distillation of fermented juice prepared from sugarcane, from concentrated sugarcane juice or from molasses left over from the sugar manufacturing process. After distillation, the drink is aged in oak barrels for a period ranging from one year to several decades, usually 1-5 years, however, when the rum takes on colour and aromas from the barrel. Lighter rums may be bottled immediately after distillation.

The rums of different countries have distinctive tastes. The distillation method itself can be a source of flavour. The distillation methods and equipment in British-administered Jamaica originate in the whisky country in Scotland, while the distillation process in Martinique, ruled by France, has been adapted from cognac manufacturers. The natural growth environments and fermentation processes also have their effects on the taste of the rum. Some rums have a naturally rich and fruity taste, while others are very neutral, depending on the properties of the raw materials and the manufacturing method used. As a result of the aging process, the rum darkens, and premium and super premium rums, which have been aged for a long time, are naturally dark brown. Burnt sugar is often added to younger dark rums to give them colour, making them a deep golden brown.

In tropical countries, the aging process in oak barrels is a delicate and challenging task, as the high temperatures speed up the process to almost three times faster than the time it takes in European conditions. For this reason, it is impossible to compare the age of rum to that of whisky or cognac. As the loss caused by evaporation from barrels is around 5% annually in demanding conditions, after 20 years there isn’t much left of the drink at all.

E&A Scheer’s strength on the markets is an understanding of the properties of rum and how to refine it. Anyone can trade in rum, but few understand it enough to be able to form harmonious blends from different grades and batches. This is why there is hardly any viable competition. We work like tailors to create a product according to the measurements we’re given. When we begin our task, we only have the customer’s vision of the type of product he or she wants. This makes the development stage particularly important.

Luckily, one is spoilt for choice where rum is concerned. E&A Scheer’s network consists of around twentyfive producers in about fiteen origins, meaning that there are a couple of hundred basic grades. The first step is to find out what the customer really wants. Starting points can vary greatly. Some know exactly what kind of aroma they want the rum to have, or where they would the rum to have its origins. Others might have a bottle and label, marketing material, distribution channels and pricelists ready, but still lack an idea of the actual product.

Product development usually begins with a rough analysis. The customer is offered a few alternatives, which guide the process in the direction of the desired aroma. Composition is adapted gradually, until the end result meets the customer’s requirements.

Development work is demanding for both the blender and the customer and can, at its longest, endure months. It is not unheard of to have to go back to the drawing board. We developed a product with one customer for over six months, but couldn’t arrive at a suitable product, and the customer’s opinions swayed along the way, too. In the end, I revisited one of the first alternatives and the customer thought it was perfect. Sometimes you have to take a long journey to get where you want to go. Blending rum is a task that requires practice and a good sense of smell. It’s not a question of tasting drinks all day; 90% of the work involves using your nose.

The brain is surprisingly good at remembering smells, which is why you can remember some smells vividly, even after a long period of time. Carsten Vlierboom himself works as one of the head blenders. He learned the skill from the company’s former master blender and by spending as much time as possible in the sample room. This is something that cannot be studied at school. Once a suitable blend has been created with the use of sample bottles, the quantities change drastically. The final batches of drink are produced on a scale of thousands of litres at the Scheer warehouse. As the quality of raw materials from suppliers can vary, the basic grades in the warehouse are blended from several batches. This ensures that the grade stays balanced, even in large quantities.

It is also favourable to blend rum because relying on a single grade from a single supplier is highly uncertain in business. There’s always the possibility of a hurricane or volcanic eruption that can destroy crops and halt production for several years. At the moment, most producers are in the Caribbean. Southern and Central American countries such as Paraguay and Venezuela are rising producing countries, with companies including Scheer searching for new partners in cooperation.

This business requires an understanding of cultures and habits. Our customers come from as far as Japan, where the working culture is astoundingly different compared to producer countries like Jamaica. Both parties need a middle man who can speak a language understood by both and can make sure that schedules, for example, are not interpreted too differently. Part of E&A Scheer’s operating philosophy is that the company does not have a production line of its own, nor does it bottle its products itself.

Our own brand of alcohol could be briefly entertaining, but if we produced one, we would be competing against our customers, which I don’t see as wise. Vlierboom likes to be open with all his cutomers. As one of the most significant operators in its field, Scheer sells its services to mutual competitors and isn’t afraid to admit it.

We’re the kind of tailor who sells suits to both Obama and Putin. The most important thing is to stop them from going into the changing rooms at the same time. The logistics of the rum trade is outsourced nowadays, and Scheer hasn’t had a naval fleet in years. Still, the rum romance of years past is still alive in the maritime atmosphere of the harbour warehouse. Seagulls caw, ships set sail and a light hint of salt floats in the air. Somewhere far away, a lone freight ship makes its way through the gentle warmth of the Caribbean with its old of aged Rum. Just like 300 years ago.

Open the Blending Tool

Browse the latest resources & industry insights to learn more about our companies and the Rum world in general.